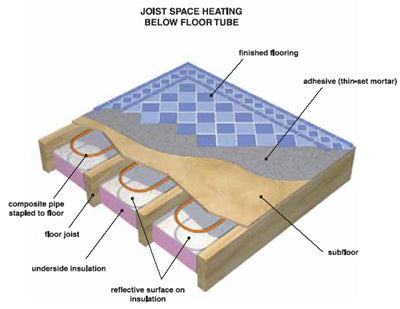

Radiant Heat Suspended Tube System

The ability of Pex to handle relatively high water temperatures makes it possible to install a suspended tube system. The tubing is placed within the air cavity between the floor joists. The tubing gives off direct radiant energy to the surfaces within the joist cavity. The outside of the tubing also gives off heat to the surrounding air, establishing a gentle convective circulation within the joist cavities. The warm air flows across the underside of the subfloor transferring more heat to it.

Radiant Heat Suspended tube systems have some unique benefits. They don’t require heat dispersion plates and thus reduce installation cost. They operate at high water temperatures under design load conditions and thus can often be piped directly to a boiler without needing a mixing valve. When the tubing is suspended below the subfloor, it is not subject to puncture from the nail points associated with installation of hardwood flooring.

As with all radiant floor heating systems, it’s imperative to install underside insulation.

This must be a reflective insulation system meaning that there is a shining reflective metal surface facing the pipe. There has to be an air gap between the pipe and the reflective layer of at least 5/8" and no more that 2" for maximum effectiveness. Never push the insulation so it is in direct contact with the plates.

Foil faced batting insulation or the aforementioned “bubble” insulation can be used. The “bubble” insulation is different from the one used with concrete. The aluminum layer is exposed on one side minimum and is always facing the piping. The insulating layer can be one or two layers of plastic “bubble” depending on the amount of insulation required.

When the space below the heated floor is also heated, use a minimum of R-11 underside insulation. If the space below the floor is partially heated, install a minimum of R-19 insulation. If the space below the heated floor is an unheated crawl space, install a minimum of R-30 underside insulation. Although these suggested underside R-values are conservative, the installer should verify they meet or exceed local energy code requirements.

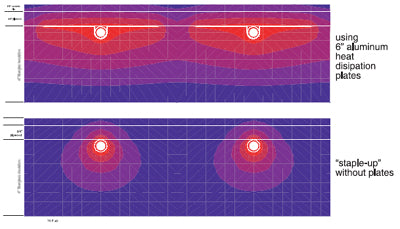

It’s possible to staple Pex directly against the underside of the subflooring without using heat dispersion plates. As discussed above this approach is only suggested for low heating load situations such as rooms that have minimal if any exterior exposure. Without either a slab or aluminum heat dispersion plates, the floor’s ability to spread the heat laterally away form the tubing is more limited. Still, when the design heat load of the space doesn’t exceed 15 Btu/hr/sqft, this installation method can deliver adequate heat output at reasonable water temperatures.

The Preferred Method is using the heat transfer plates. This allows you to lock the Pex into the heat transfer plate and staple the plate to the underside of the sub-floor. Using this method allows for lower water temperatures and less fuel consumption.

The following image illustrates the heat transfer process during joist space installation using heat transfer plates or direct staple up. The image speaks for itself and gives very good reasons to consider using the heat transfer plates wherever it is possible.